- Home

- About Us

About Us

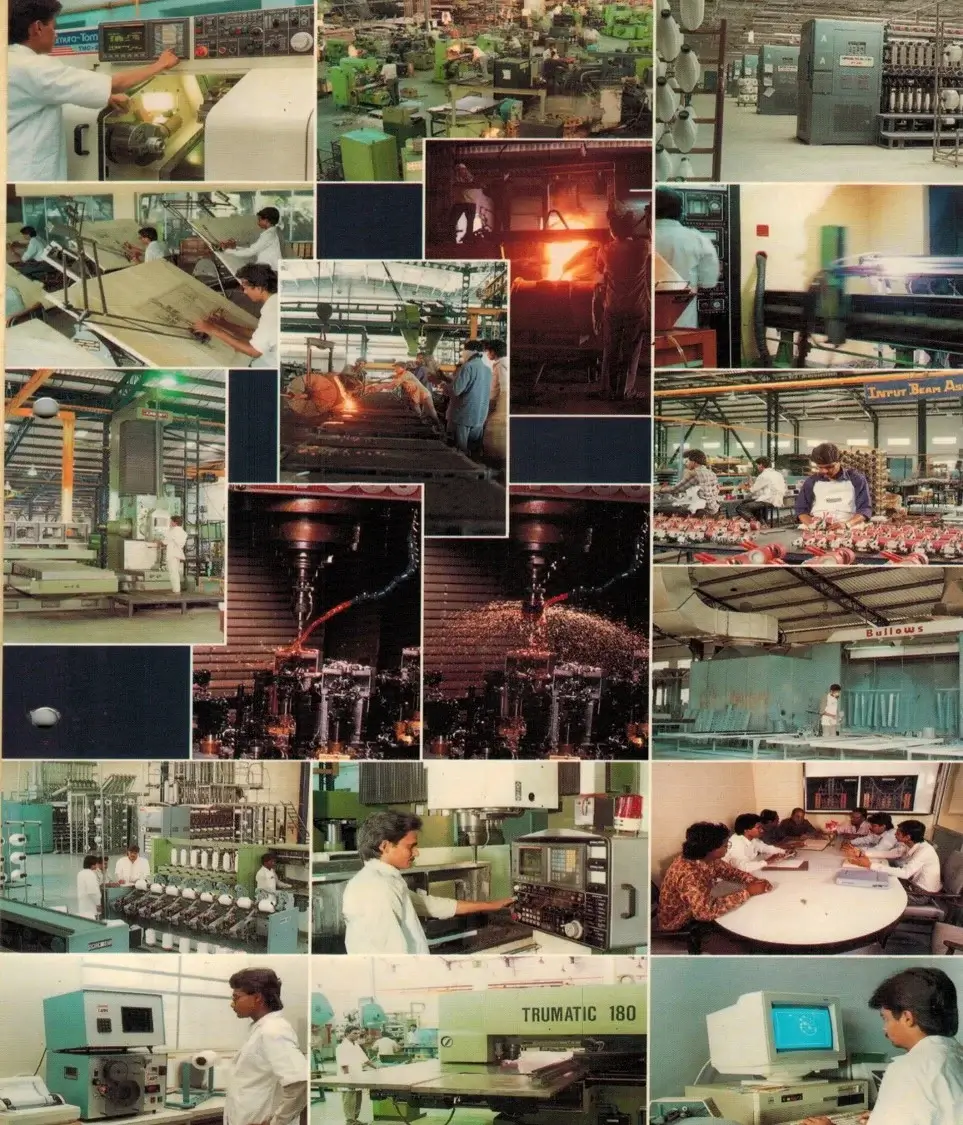

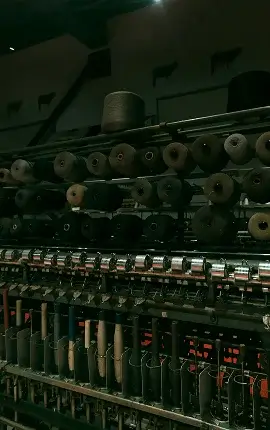

HIMSON, a well established name in the field of Synthetic yarn processing machinery. The group is a leading name for Draw Texturizing machine manufacturing, along with undertaking WET Industry projects, Twisting and Winding machine manufacturing and providing solutions for Fabric drying and coating. HIMSON group was established in 1926 for manufacturing quality fabrics with just few looms. In the late 40’s, the group blossomed and expanded in the loom shed activities as well as Dyeing and Finishing processes. Further, Lace and embroidery units were established and the group achieved steady growth with the focus on Textiles. In 1972, the Engineering division was established, which started with manufacturing of Twisting and Winding machines. The group entered into a technical collaboration with M/s Earnest Scragg Ltd, UK (later acquired by Reiter group), and since then, expansion in product portfolio has never stopped.

The HIMSON Group traces its origins back to 1926, when it began with just a few looms dedicated to producing quality fabrics. By the late 1940s, the group experienced steady growth, expanding its loom shed operations and adding Dyeing and Finishing processes. Over time, lace and embroidery units were also established, further strengthening the group’s presence in the textile sector and ensuring consistent, focused growth.

Employees

Management

Technical

History

In 1972, the Engineering division was established, which started with manufacturing of Twisting and Winding machines.

Himson started its activities 50 years ago with only few looms to manufacture quality fabrics. Since then the group activities have grown from strength. HIMSON first concentrated on expansion in the loom shed and subsequently dyeing and finishing houses were added for further growth thought forward integration. Further lace and embroidery units were established as a move towards complimentary diversification. Till this time growth was slow and steady with focus only on textiles.

Our brief work

WET PROJECTS:

METERING PUMPS:

THE EMPLOYEES:

The company has about 1200 employers on its rolls, of which about 150 (13%) are management/Executives staff and 150 are Technical staff. The company has also helped developed about 150 ancillary units owned by qualified engineers. This has helped the company easily absorb the latest technology and adapt the same to meet the global requirements.

THE INFRASTRUCTURE:

The fast growth has been sustained by installing modern Computerized Numerical Machining Centers to achieve highest accuracy and setting up a fully equipped R&D Center. Further it has a high-tech, state of the art STANDARDS ROOM for verification and calibration of measuring tools. The STANDARDS ROOM is equipped with 3D CNC Coordinate Measuring Machine along with other latest state-of-art machines & equipments.

We built the largest biogas plant in Europe and the third largest in the world. Its electrical power is 26 MW!

There are many variations of passages of available but the majority have suffered alteration in some form, by injected humou or randomised.

Production Halls

Tons of Products per Month

Patents in 62 Countries

People in a Team

Awarded quality

Our products are manufactured and rigorously tested to the highest quality and manufacturing standards in US. We really put a lot of thought into our products so you don’t have to.

Hard on the outside smart on the inside

Even gaseous or liquid pollutants won’t harm the sensitive solar cells. The glass is applied on both sides and lamination bonded, making it impossible for moisture

- Protection against mechanical stress

- Protection against environmental influence

- UV protection

We provide innovative Product Solutions

As your precision motion partner, we work closely with your team to improve your processes, products and productivity.

- Inefficient Operations

- ADVANCED TECHNOLOGY

- Inaccurate Inventory

- DELIVERY ON TIME

- No Real-time Data Access

- CERTIFIED ENGINEERS